General, Product information

Non-return valve - what is it and what is it used for?

Check valves, also known as non-return valves, ensure that water or gases can only flow in one direction. They open automatically in the direction of flow and close automatically as soon as the direction of flow begins to reverse. Typical areas of application for non-return valves include mixer taps, gas pipes and radiators.

The valves consist of a disc and a spring. The disc presses against the spring in the direction of flow, opening the pipe cross-section. If there is no flow or the flow reverses, the pressure on the spring ceases so that the pipe cross-section is immediately closed.

Non-return valves in mixer taps

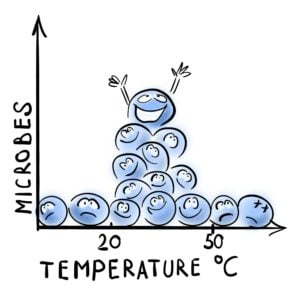

In mixer taps, non-return valves prevent cold water and hot water from mixing. On the one hand, such mixing is not energy-efficient. On the other hand, lukewarm water provides ideal living conditions for bacteria. In order to shorten the distance between the non-return valve and the tapping point, the valve is always installed just before the tap. It is usually located in flexible Pex hoses.

Low maintenance intensity can lead to malfunctions

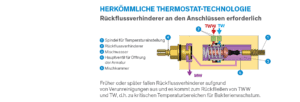

Today, the hot and cold water is mainly mixed before the closing mechanism. This means that the hot and cold water pipes are not physically separated - even if the tap is closed. Due to pressure differences between the two pipes, cold and hot water are mixed. As a result, we only get slow-flowing or even stagnant hot water. Check valves are designed to prevent this. However, in practice, these are rarely or never maintained. This can lead to limescale residues and other impurities and subsequently to malfunctions.

Closing mechanism upstream of the mixing chamber makes backflow valves superfluous.

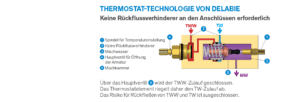

France is now taking a technically new approach with the French standard NF 077 MM. The standard specifies the closing mechanism upstream of the mixing chamber. The arrangement of the closing mechanism upstream of the mixing chamber, which eliminates the need for backflow preventers, would indeed be a small step forward for the valve market. Revolution. This is because the majority of today's electronic or thermostatic fittings do not yet fulfil this requirement.

Our partner Delabie has developed a Unique, patented system which ensures that the hot and cold water inlets of thermostatic taps are closed directly at the connections. This completely eliminates the need for vulnerable backflow preventers and the risk of cold water or hot water flowing back out of the tap. More information on how the new cartridges work can be found below.